Are we Digital Twinning yet?

In this latest blog, Aidan Mercer, Marketing Director from buildingSMART International discusses "digital twins" as a context for project delivery and asset management. In this blog you can read about project examples of how digital data has enabled the right context for a digital twin and how open standards offer data alignment.

What is a digital twin?

I don't know that the term "digital twin" does itself justice. It sounds a bit static. Adding an "ing" to words tends to evoke more of a forward motion. Maybe even adds a continuous connotation. We of course shouldn’t get hung of on precise wording, but at times it can be an important perspective for an important topic.

A “digital twin” is a representation of a physical asset or system in a digital form. A digital twin allows visual performance insights through continuous data inputs. If you didn’t already know, it is the current buzzword in the industry today. It has gained significant traction in construction due to a variety of reasons. Against an unfortunate backdrop of poor productivity and limited technological adoption, construction seems to be the focal point for disruption and change. For many years, organizations have had business models that offer razor-thin margins and high levels of risk associated with projects. It seems; however, the tide is turning. There are a variety of reasons as to why digital twins are in the spotlight, and this can depend on the context that’s applied to deliver better outcomes.

Digital twins are yet to fully deliver against their promise. This is by no means meant to be a negative statement. There’s understandable trepidation, with some unconvinced observers or practitioners believing it could just be merely an overlay of information. On the other hand, some organizations feel they have been doing “digital twins” for many years. This may lie in understanding what a digital twin is and what it can be. One thing we can be sure of, the industry has high expectations for digital twins because they promise augmentation of reality with performance benefits. Essentially – companies can make better-informed decisions to deliver better outcomes. This is particularly important for operations and maintenance as a method for repeatable and automated capabilities to deliver better outcomes. The Centre for Digital Built Britain has provided an in-depth report on the benefit of a national digital twin called Gemini Principles.

The dichotomy has arisen because of data alignment issues and closed workflows that have limited a fully functioning digital twin. I would argue that given the confusion, a digital twin is a context for delivering projects or being able to improve asset management. Digital twins, however, require an open information environment in order to align and access data more effectively.

A Context for Project Delivery

Most projects today begin with some form of BIM model. Ideally, this BIM model will contain valuable asset information that if used correctly can be useful for a digital twin. One issue that does not aid the success of a digital twin is the often-obscure file formats that an engineer may use in early project phases. However, open source technology and rapid advancements in new technologies are significantly changing the landscape. For example, reality capture technology offers a quick and easy digital capture methodology with accurate and repeatable outcomes. The ease with which a site can be captured in digital format is being enabled by drones and laser scanning technology that delivers accurate, engineering-ready digital models that can add context to existing BIM models.

These models, however, require alignment in order to be universally useful. Alignment is needed in order to create a workflow to connect digital data, otherwise, we find data can easily become inaccessible and dark. Digital ways of working are being enabled by buildingSMART today. Open data standards provide a collaborative platform for exchanging and managing digital data – or digital workflows. IFC, for example, offers assurances to the client that digital data created during the design and construction phase can be used in-perpetuity – avoiding obscure data formats that expire or become inaccessible at a later date. An example of a context for project delivery can be found in the following two projects.

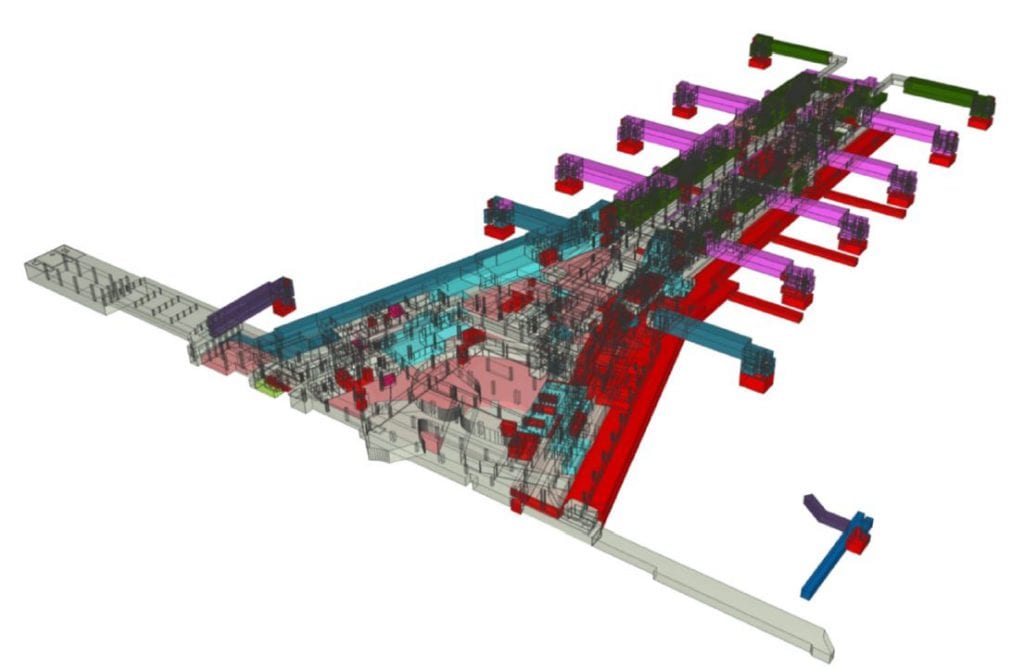

Aas-Jakobsen, with their winning 2018 buildingSMART Award for Design project titled, Team_T, Avinor Airport, cited the IFC mandate for BIM models as the reason for on-time delivery and under budget. Design teams had a large number of software applications, but rather than standardize on one file format, the client wanted to push an openBIM approach. This meant utilizing IFC as an exchange standard for all contractors allowing them to choose their preferred authoring applications. This bound the various project teams, contractors and software vendors, into delivering genuine interoperability. The open project environment also enabled BIM data to be accessed in a later phase.

Another example from a 2018 buildingSMART Award winner for Construction is “Project Pontsteiger”. Digital engineering models provided offsite manufacturing so that no cutting and drilling on site would occur. Digital demand models were developed to look at all disciplines to a level at which production could participate in making their own supply models. For each discipline within the demand models, a production partner was brought in. BIM coordinators were appointed onsite, coordinating and checking all models and working together with the site engineering team who were responsible for the program, 2D output and contracts. By coordinating teams, and utilising BIM models as a decision-making context, the teams were able to make better decisions before any onsite construction, helping to deliver on-time and under budget.

These project delivery examples provide better understanding of the digital context for planning to construction. The need go beyond BIM deliverables will offer fruitful outcomes if new sources of data can be connected. A digital twin needs continuous data inputs. This is not an easy task. Data alignment and mapping are needed with data standards and templates that can add layers and attributes to data so that the digital twin knows that a door is actually a door, and the specifications of that door are accurate and manageable. If the information in a digital twin is inaccurate it is rendered useless. One example that this has worked well in is the use of barcodes for asset recognition, giving the digital twin precise information about the asset. This also helps to link a new network of product manufacturers who can provide relevant information about an asset or component.

A Context for Asset Management

A context for asset management is where many feel a digital twin will deliver the most value. The long-term benefit for a digital twin is the potential in asset reliability, integrity and performance. If AI, machine learning and automation can be applied to digital twins then decisions about assets could soon become seamless. Getting to this utopia, however, is more of a challenge. For example, today, companies have a major challenge in managing change and synchronizing changes to apply advanced analytics for better decision-making. This is primarily because data is not aligned and often inaccessible for performance benefits.

One such example of a digital context that delivers asset management benefits is in the project by Minnucci Associati s.r.l. and their winning project from the 2018 buildingSMART Award category for Operations and Maintenance. By developing a common data environment (CDE), the project could house over 12,500 components and 44 federated digital models to create asset information models. These models connect to the existing work order management system to help make better decisions when operating Naples Station. The station itself has over 400 operational trains and a variety of public shops and spaces, therefore a context for helping run the facility was critical.

The key benefit of this project was to provide a context to manage change. A digital twin needs to change and adapt to be effective. To make decisions in real-time via a digital twin requires a multitude of data to be made available in a 3D model. There is no doubt that the software is there today. Open source platforms are available on GitHub for users to trial and add their own expertise to. This is an exciting opportunity and probably the real value-add for digital twins – the ability to adapt, change and maximize the potential of digital workflows for better decision making. The opportunity for owner-operators is better lifecycle planning by making projects open and accessible. Only then will we be digitally twinning.

buildingSMART hosted a roundtable on “Digital Twins” with Siemens at the International Standards Summit in Dusseldorf on 26th March 2019. Amongst the attendees, it was universally agreed that a pilot project would be hugely beneficial for the industry. buildingSMART is looking forward to leading the way on the development of an open standard for a digital twin.

Keep an eye out for more news soon.